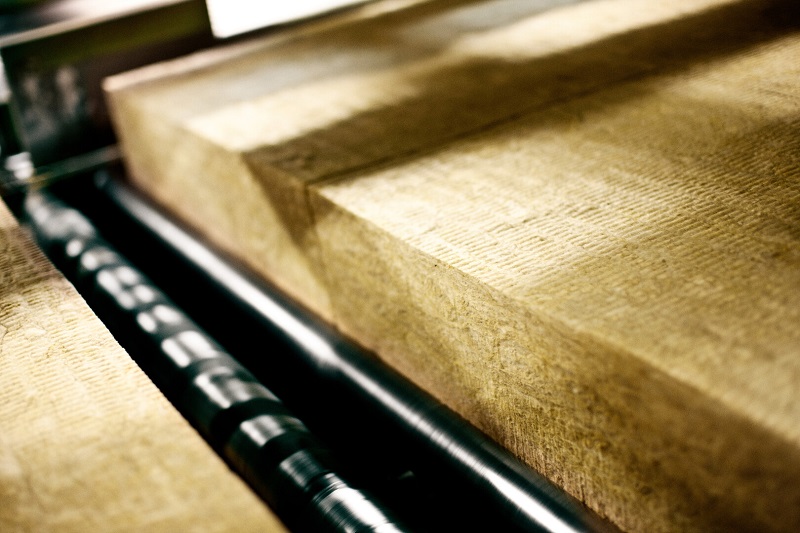

Mineral wool is an insulation material made from either glass or rock mineral fibers. Hence there is a basic division into glass wools and rock wools.

Glass wool is obtained from glass cullet and quartz sand, which is melted at a temperature of about 1000 degrees C.

Rock wool, on the other hand, is produced from basalt doped mostly with gabbro, dolomite and limestone. The technological process of melting rock wool requires a significantly higher temperature, i.e. 1500 degrees celsius

Rock wool, like glass wool, is produced by a technological process that involves melting the raw material to the consistency of lava. Such an intermediate product is then poured onto spinning disks, which spin at a speed of several thousand revolutions. Due to centrifugal force, the melted raw material splashes and solidifies in the air, forming fibers. The fibers thus obtained are mixed with a binder and hydrophobic agents to ensure resistance to absorption of moisture from the air. The next stage of the production cycle is molding, where, depending on the type of product, it obtains the appropriate arrangement of fibers and the initial shape.

The next stage is the polymerization chamber, where the binder is set at a temperature of several hundred degrees Celsius. Once cooled, the wool is cut to final size and packaged.

It is interesting to note that a similar phenomenon sometimes occurs naturally, during a volcanic eruption, where molten volcanic rock cools in the air, forming shreds of fibers. In Hawaii, this material is called hair of the goddess Pele – a legendary resident of the Kilauea volcano. Observation of this natural phenomenon is credited with the invention of mineral wool.

Mineral wool as an insulating material is characterized by low thermal conductivity and very good acoustic performance.

It is widely used as an acoustic separator in partitions, ceilings and even in roadside noise barriers.

As thermal insulation, due to the very wide range of finished products on the market, we can use it to insulate ceilings, roofs, facade walls, foundations, floors, chimneys and plumbing components. An interesting application is the hydroponic cultivation of plants, where mineral wool replaces the natural substrate.

Mineral wool is characterized by very good performance in contact with moisture. On the one hand, it is vapor-permeable, which makes the building insulated with wool “breathe” and provides unprecedented comfort in the rooms where it was used, creating a specific microclimate. On the other hand, it is a material that after getting wet, for example, due to flooding we can reuse after drying – especially rock wool.

It is worth noting that mineral wool is a highly ecological product. Firstly, as a natural product it does not interact with the environment, and secondly, it is completely recyclable allowing the material to be used again and again, something that cannot be said about polystyrene or polymer foams.

Another important feature of mineral wool is that it is a completely non-flammable product. All mineral wool products have a non-flammability class A1. Even when exposed to extremely high temperatures, mineral wool does not smoke or release toxic substances, which are the most common cause of death during fires. Here it is worth mentioning the superiority of rock wool over glass wool. Rock wool has a much higher melting point, and consequently, when melting, it does not tend to so-called “drip”.

When discussing the differences between glass wools and rock wools, it should be made clear that it is not possible to say unequivocally that one technology is better than the other. They are different products with different properties. It all depends on the application of the product.

Much depends on the personal preferences of designers and contractors. From general aspects, it is assumed that glass wools can have a lower lambda heat transfer coefficient, and rock wools have lower water absorption. Glass wools have a greater ability to so-called “settling” compared to rock wool. The choice of glass wool – rock wool is not obvious and it all depends on the case study, because sometimes the application clearly favors rock wool and sometimes glass wool. There are also many cases where the use of one and the other will be the same, and the only determining factor will be the price.

Comparing mineral wools (glass and rock) with products such as Styrofoam and especially spray foam, there is a clear advantage in favor of wool. It is a natural, non-toxic, non-flammable, smoke-free, ‘breathable’ and vapor-permeable material.